How Siemens Model Numbers Reflect Engineering Logic

In the world of industrial instrumentation, Siemens is known not only for measurement accuracy, but also for its strong system integration philosophy. Siemens instruments are designed to fit seamlessly into automation architectures such as SIMATIC PCS 7, TIA Portal, and industrial communication networks. One of the most distinctive characteristics of Siemens instruments is their structured and modular model code system.

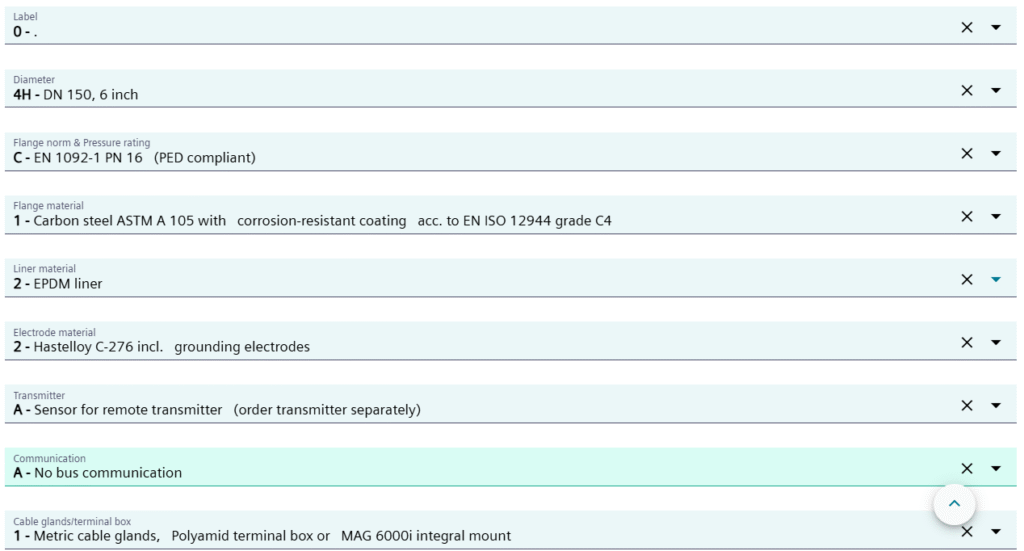

At first glance, a Siemens model number may look complex:

7ME6520-4HC12-2AA1-ZN02+K08

However, this is not a random combination. It is a configuration map that defines the instrument’s platform, measurement principle, mechanical design, communication interface, and project-specific options.

This article explains how Siemens instrument model codes work, using the SITRANS ultrasonic level transmitter as a representative example.

1. Siemens Model Codes Are System-Oriented, Not Product-Oriented

Unlike some brands that emphasize sensor-level customization first, Siemens model codes reflect a system-first design philosophy.

Each section of the model number answers a specific engineering question:

- Which Siemens measurement platform is used?

- What measurement technology is applied?

- How will the instrument communicate with the control system?

- What mechanical and electrical standards are required?

- Are there project-specific or optional features?

As a result, Siemens model numbers are often long but logically segmented.

2. Platform and Product Family: What “7ME6520” Means

The first block of the model code defines the product family and measurement technology.

7ME6520

7ME: Siemens process instrumentation product group

6520: SITRANS ultrasonic level transmitter series

📌This part identifies the core measurement principle and platform, independent of configuration details.

3. Hardware Variant and Measurement Design: “-4HC12”

The second segment specifies the hardware variant, including sensor performance and design generation.

-4HC12

This section typically encodes:

- Transducer type and performance class

- Application suitability (liquids, solids, open channels)

- Design revision or regional variant

⚠️Engineering note:

Two instruments from the same SITRANS family can behave very differently in challenging applications based solely on this segment.

4. Power Supply and Output Signal: “-2AA1”

This part defines how the instrument is powered and how it communicates with the automation system.

-2AA1

Typical Siemens logic here includes:

- Power supply (e.g. loop-powered or AC/DC)

- Output signal (4–20 mA, HART, digital interface)

- Compatibility with Siemens control systems

📌This is a critical checkpoint for PLC/DCS compatibility, especially in retrofit projects.

5. Special Version Identifier: “-ZN02”

Siemens uses “Z” codes to represent non-standard or extended configurations.

-ZN02

Z-codes often indicate:

- Special mechanical designs

- Application-specific adaptations

- Project or industry-specific requirements

These options are usually not visible from the base product description, but are essential for correct ordering and lifecycle support.

6. Optional Functions and Accessories: “+K08”

Unlike fixed model segments, Siemens uses “+K” option codes to add selectable functions.

+K08

K-options may include:

- Display and user interface enhancements

- Additional diagnostics or firmware functions

- Installation or commissioning accessories

📌This modular option structure allows Siemens instruments to be expanded without changing the core platform.

7. Why Siemens Model Codes Look Different from Other Brands

Siemens model numbers are designed to support:

- Global standardization

- System-level integration

- Long product lifecycle management

Instead of encoding every detail into a single compact string, Siemens uses clearly separated functional blocks, making the code easier to audit during engineering reviews and project handovers.

Conclusion: A Siemens Model Code Is a System Specification

A Siemens instrument model code is not just a sales identifier—it is a technical contract between the instrument, the control system, and the application.

Understanding the structure of Siemens model numbers helps engineers and buyers:

- Verify system compatibility before installation

- Avoid configuration mismatches

- Reduce commissioning time

- Ensure long-term spare parts consistency

If you are reviewing a Siemens instrument model code and need confirmation that it truly fits your application or automation environment, a structured code-level review can prevent costly rework later.

For detailed technical specifications, application advice, or commercial inquiries regarding a wider range of industry brands, please contact us via WhatsApp: +86 132 7933 7527 or Email: info@antletstech.com. Our experienced engineering team is ready to support your project.

-

Temperature Measurement59 products

Temperature Measurement59 products -

Pressure Measurement169 products

Pressure Measurement169 products -

Level Measurement263 products

Level Measurement263 products -

Flow Measurement183 products

Flow Measurement183 products -

Liquid Analysis36 products

Liquid Analysis36 products